CO600F1S涂层测厚仪探头,磁性, 1600μm

型号:CO600F1S

仪器产地:国产其它测厚仪

测厚仪探芯采用超强耐磨材料制作,大大提高了探头的使用寿命,保证了仪器的测量 精度和重复性。这样的设计一改市场常见探头因内芯磨损而测量欠准确、或镶嵌的红宝 石脱落等缺陷。

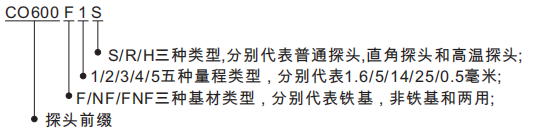

探头编号

执行标准:ISO 2178/2360/2808、ISO 19840、ASTM B244/B499/D1186/D1400

探头选型

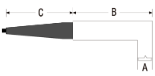

| 形状 | 探头型号 | A | B | C | 量程 | 精度1 | 最小净空高度 | 最小测试半径 | 最小基材厚度 |

| CO600F1S | 9 | 40 | 50 | 1.6mm | ±1-3%或2.5μm | 80mm | 5mm | 0.8mm |

| CO600F2S | 9 | 40 | 50 | 5.0mm | ±1-3%或20μm | 80mm | 5mm | 0.8mm | |

| CO600F5S | 9 | 40 | 50 | 0.5mm | ±1-3%或2.0μm | 80mm | 5mm | 0.8mm | |

| CO600F1H | 9 | 40 | 50 | 1.6mm | ±1-3%或2.5μm | 80mm | 5mm | 0.8mm | |

| CO600F2H | 9 | 40 | 50 | 5.0mm | ±1-3%或20μm | 80mm | 5mm | 0.8mm | |

| CO600N1S | 9 | 40 | 50 | 1.6mm | ±1-3%或2.5μm | 80mm | 5mm | 0.3mm | |

| CO600N2S | 9 | 40 | 50 | 5.0mm | ±1-3%或20μm | 80mm | 5mm | 0.3mm | |

| CO600N5S | 9 | 40 | 50 | 0.5mm | ±1-3%或2.0μm | 80mm | 5mm | 0.3mm | |

| CO600F1R | 9 | 40 | 50 | 1.6mm | ±1-3%或2.5μm | 30mm | 5mm | 0.8mm |

| CO600F2R | 9 | 40 | 50 | 5.0mm | ±1-3%或20μm | 30mm | 5mm | 0.8mm | |

| CO600N1R | 9 | 40 | 50 | 1.5mm | ±1-3%或2.5μm | 30mm | 5mm | 0.3mm | |

| CO600N2R | 9 | 40 | 50 | 5.0mm | ±1-3%或20μm | 30mm | 5mm | 0.3mm | |

| CO600F3S | 16.5 | 40 | 50 | 13.0mm | ±1-3%或50μm | 80mm | 10mm | 1.0mm |

| CO600F4S | 24 | 60 | 50 | 26.0mm | ±1-3%或100μm | 120mm | 30mm | 1.0mm |

*高温探头温度为250℃

技术参数

型号 | CO600F1S |

测量原理 | 磁感应 |

测量范围 | 1600μm |

误差范围 | ±1~3%或2.5μm |

最薄基体 | 0.8mm |

测试环境 | 磁性金属基材 |

探头 | 普通探头 |

最小净空高度 | 80mm |

最小测试半径 | 5mm |

探头接触面直径 | 9mm |

产品发布日期:2026.01.24

德国高科检测技术有限公司